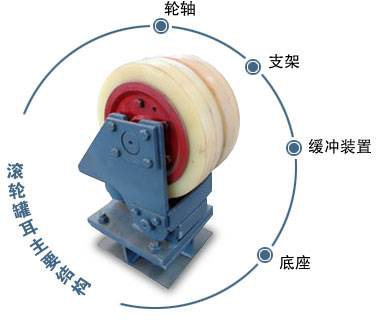

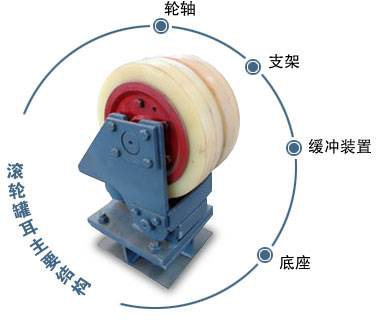

Roller can ear is a type of roller can ear used for lifting containers in vertical wells. Its structure consists of a base, a swing arm, a roller, and a buffer; The combination of roller drum ears and the characteristics of mines in China provides convenient conditions for the replacement of new roller guide devices for lifting containers currently in operation, and is widely used in industrial production sectors such as mining and coal.

Roller can ear classification

Roller can ear, buffer roller can ear, lightweight roller can ear, hydraulic roller can ear, buffer, roller can ear.

Characteristics of Roller Jar Ears

1. Replacing traditional buffer structures with hydraulic buffers provides high load-bearing capacity, smooth operation, high reliability, long lifespan, and easy adjustment and maintenance.

2. The base and other components are made of new materials, which have higher overall structural strength and stronger impact resistance.

3. The buffer reset pressure is small, which can effectively avoid abnormal collisions between the roller and the tank channel. It is transmitted to the shock absorber through a lever, while also playing a guiding, buffering, and stabilizing role.

The sliding friction between the can channel and the can ear has changed to rolling friction, thus reducing power consumption, lowering noise, and greatly reducing the wear of the can channel and the can ear. Thus, the service life of the can channel and can ears has been improved.